not just a floor. a statement.

not just a floor. a statement.

BULLETPROOF.

BULLETPROOF.

High gloss is the least scratch resistant topcoat.

A black Metallic floor is the least scratch resistance floor.

Here is our high gloss, black, metallic floor being hit with a hammer:

Can you imagine how durable our flake, semi-gloss, satin, white or lighter floors are?

High gloss is the least scratch resistant topcoat.

A black Metallic floor is the least scratch resistance floor.

Here is our high gloss, black, metallic floor being hit with a hammer:

Can you imagine how durable our flake, semi-gloss, satin, white or lighter floors are?

epoxy done right.

welcome to the HIGHTEST QUALITY custom epoxy flooring in the Greater Cincinnati area. unmatched attention to detail, unbeatable pricing, and fast, transparent service — made possible by our exclusive access to industrial material with the highest-rated appearance and proven durability in the industry, and our willingness to invest in what no other company in the Midwest has ever used.

in addition to fully grinding your concrete down to ensure a perfect bond, we hand-grind and hand-sand every corner, wall, and inch for perfect coverage. We follow this by applying the market’s best topcoat to ensure a finish that stays flawless under cars, sun, and time

only us.

key METALLIC features only we offer:

hand grinded edges

instead of saving time/money by only using a large grinder, we hand grind all of our edges

THICK POUR

every. and I mean every epoxy installer uses less epoxy to save costs. We don't.

black basecoat

we apply extra pigment to our MPC moisture barrier basecoat on all non-white floors.

moisture barrier

there is not a single installer in the mid-west that applies a moisture barrier on every project.

customization

unlike other companies, we have the ability to install Custom Decals / Designs / Color Combos.

hand sanded walls

not only do we hand sand every edge, but we also add 3-in brush work to ensure a perfect application.

no odor.

in addition to completely sealing your garage off from the rest of your home, our materials are all almost completely odorless.

3 LAYER TOPCOAT

our gloss topcoat is 3 the only one in the industry that can be applied in 3 layers.

slip resistance

we apply aluminum oxide in our semi gloss topcoats, more in areas with more foot traffic like stairs. etc.

why this is essential.

Floors poured at 30–40 mils typically last 2.7-3 times longer than coatings applied at standard 10–15 mils. — CoatingsPro Magazine (2020)

Real estate listings that highlight designer epoxy floors (with unique finishes) sell 17.2-18% faster. — Zonda Residential Design Trends Study, 2023

Epoxy floors installed without a moisture barrier show visible failure in as little as 2–3 years. — International Concrete Repair Institute (ICRI)

A black or dark basecoat enhances the 3D depth of metallic epoxy designs by up to 300%, especially with high-luster pigments. — Concrete Decor Magazine, Metallic Floor Systems Guide

Up to 85% of epoxy flooring failures are linked to moisture vapor transmission through concrete slabs. — National Flooring Contractors Association (NFCA)

Epoxy floors installed without a moisture barrier show visible failure in as little as 2–3 years. — International Concrete Repair Institute (ICRI)

A black or dark basecoat enhances the 3D depth of metallic epoxy designs by up to 300%, especially with high-luster pigments. — Concrete Decor Magazine, Metallic Floor Systems Guide

Up to 85% of epoxy flooring failures are linked to moisture vapor transmission through concrete slabs. — National Flooring Contractors Association (NFCA)

Epoxy floors installed without a moisture barrier show visible failure in as little as 2–3 years. — International Concrete Repair Institute (ICRI)

Floors poured at 30–40 mils typically last 2.7-3 times longer than coatings applied at standard 10–15 mils. — CoatingsPro Magazine (2020)

Real estate listings that highlight designer epoxy floors (with unique finishes) sell 17.2-18% faster. — Zonda Residential Design Trends Study, 2023

Epoxy floors installed without a moisture barrier show visible failure in as little as 2–3 years. — International Concrete Repair Institute (ICRI)

What Our Customers Are Saying

5.0 Google ★★★★★ | ![]() Customer Reviews

Customer Reviews

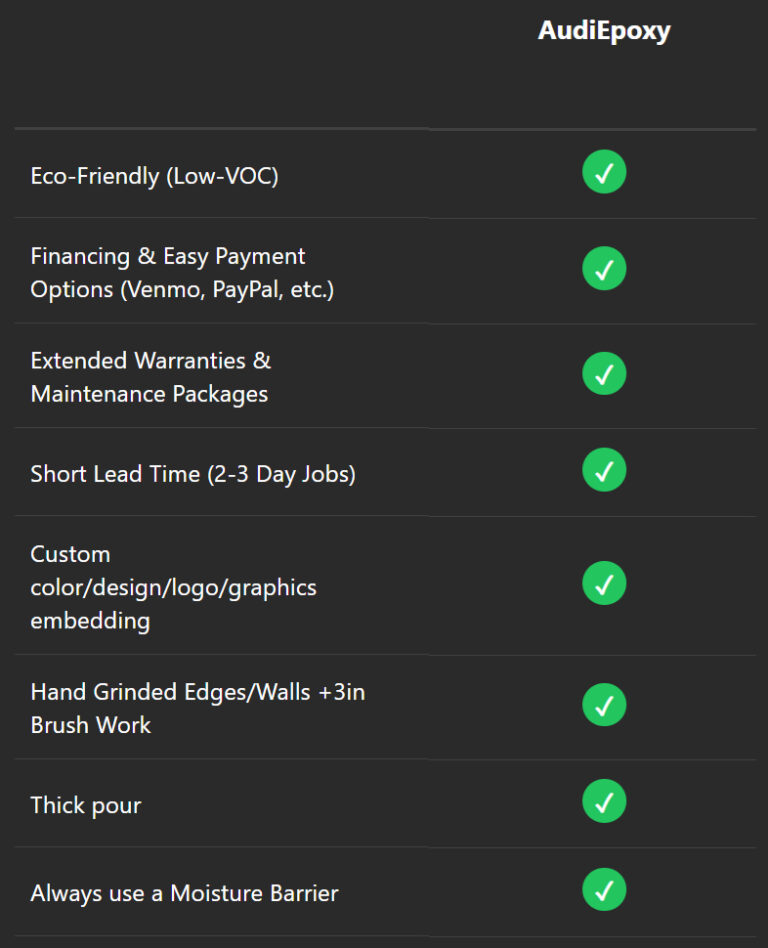

The only company in Cincy to check all the boxes!

If you don't believe it, call our competitors and ask! That's what we did.

a 2 day job — METALLIC

Contact us about your space

We provide free quotes through text, home visit, or email.

In Person Quotes

send the word: "EPOXY" to 773-708-3004 or adi.divanovic@gmail.com to set up a phone call and schedule a home visit.

Text/Email Quotes

Message us at 773-708-3004 or adi.divanovic@gmail.com with your square footage and pictures of your space.

Questions?

No problem, we’ll work to decide on where to leave your items during the project and move it ourselves.

1-3 days, depending on whether or not things need to be moved prior to the project.

Yes, epoxy flooring is easy to clean and maintain. Occasional sweeping/mopping are sufficient to keep it looking new.

This is a question most installers are afraid to answer. Our floors last anywhere from 20-25 years, and usually just require a quick refresh to keep them lasting even longer.

We apply Aluminum Oxide powder, a very fine substance that increases slip resistance and gives your topcoat a slightly more satin finish. We do this before cross rolling our topcoat. **side note: Most installers apply their Aluminum Oxide powder completely before intalling their topcoat, which leads to an uneven finish and makes it ineffective as it then just sits under the topcoat!

Yes. You can tell us and we will adjust how much aluminum oxide we apply on the floor. Additionally, we can apply MORE aluminum oxide on higher traffic areas like stairs.

Yes. We apply Cabosil powder into our epoxy to give it a peanut butter like texture. This makes it possible to individually epoxy any vertical surfaces like stem walls/stairs.